In the galvanizing industry, identification is not optional. It is a critical part of keeping production organized and accurate. Every piece that moves through the plant needs to be labeled in a way that remains readable from the beginning of the process to the end. When a tag fails, it can cause delays, errors, and unnecessary material loss. Durable galvanizing tags have become essential for operations that want dependable identification throughout every stage.

As plants continue to handle extreme heat, chemicals, and heavy material movement, traditional labels fall short. InfoSight’s Kettle Tag Plus and Kettle Tag Plus EZ were developed to solve this problem and provide long-lasting durability in environments where other tags cannot survive.

Why Identification Matters in the Galvanizing Process

Hot-dip galvanizing exposes materials to intense heat, corrosive cleaning solutions, steam, and mechanical force. A tag that breaks down during any one of these steps puts the entire job at risk. Lost identification often leads to rework, incorrect shipments, and missed deadlines. Plants that rely on precision simply cannot afford to use unsuitable tags.

There is also a growing demand for documentation and traceability. Customers and industry certifications often require accurate tracking throughout all stages of production. Reliable metal barcode tags help ensure each piece can be identified correctly, even when thousands of items pass through the plant every week.

Kettle Tag Plus and Kettle Tag Plus EZ: Engineered for Survival

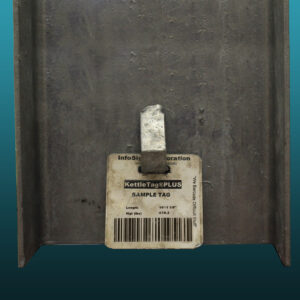

The Kettle Tag Plus is designed specifically for hot-dip galvanizing environments. It is printed using an InfoSight metal tag printer and then manually sealed with a protective laminate. This quick step locks the printed information under a durable surface that holds up to the heat and chemicals used during galvanizing. It is a cost-effective choice for facilities that do not mind a small amount of post-print handling.

Plants appreciate the flexibility of applying the laminate themselves and the strong durability it provides once applied. The tag stays intact and readable throughout the cleaning, pickling, galvanizing, and finishing stages.

Kettle Tag Plus EZ

The Kettle Tag Plus EZ takes convenience to another level. It is pre-laminated, and the InfoSight metal tag printer marks directly through the protective layer. Nothing needs to be done after printing. Operators simply print the tag and attach it to the material. This version is ideal for high-volume operations where every minute counts and consistency is important.

The pre-laminated construction eliminates the chance of missed steps and ensures every tag receives the same level of protection. Its simplicity allows busy facilities to maintain steady workflow without slowing down for additional processing.

Time Savings and Greater Efficiency

The Kettle Tag Plus EZ saves time by removing the lamination step entirely. Even a few seconds per tag adds up quickly during large production runs. By printing directly through the laminate, operators can keep work flowing smoothly without interruptions.

The standard Kettle Tag Plus also offers a more efficient option than handwriting or using non-durable labels. Laser-marked tags provide clear, consistent identification that reduces errors caused by unclear writing or smudged information.

Reduced Labor and Lower Overall Costs

Durable galvanizing tags reduce costs by preventing lost identification, rework, and production delays. When tags stay readable throughout the process, workers do not have to repeat steps or try to identify unmarked pieces. This directly reduces wasted time and material.

Both versions of the Kettle Tag help operators work more efficiently. Employees spend less time replacing failed tags and more time focusing on productive tasks. Workflows stay steady, and plants benefit from fewer disruptions.

Traceability Through Harsh Environments

Traceability is an important part of modern galvanizing operations. Accurate identification supports quality control, customer documentation, and audit requirements. When paired with an InfoSight LabeLase metal tag printer, Kettle Tag products provide clear, long-lasting marks that remain readable after exposure to heat, chemicals, and outdoor conditions.

This level of durability gives galvanizers the confidence that every piece will remain traceable from start to finish. It also supports long-term recordkeeping and strengthens customer trust in the final product.

Choosing the Right Galvanizing Tag

The Kettle Tag Plus is a strong choice for facilities that want a cost-effective solution and do not mind applying the laminate by hand. It works well in environments where batch sizes vary or where operators have time for simple post-print processing.

The Kettle Tag Plus EZ is ideal for high-volume plants or teams that prefer a simple print-and-go workflow. Since it is already laminated, it saves time, prevents skipped steps, and delivers consistent results across all shifts.

Both versions offer dependable durability and long-term identification. They help plants move away from unreliable labeling methods and adopt a solution built specifically for the demands of galvanizing.

Identification is Key in Harsh Environments

Identification in the galvanizing process must be as tough as the steel being processed. InfoSight’s Kettle Tag Plus and Kettle Tag Plus EZ provide long-lasting, reliable identification designed to survive extreme environments from start to finish. When used with an InfoSight metal tag printer, these galvanizing tags offer stronger traceability, reduced labor, and lower overall costs.

If you would like, I can also prepare a shortened web version, create a PDF layout, or develop social media posts to help promote this blog.