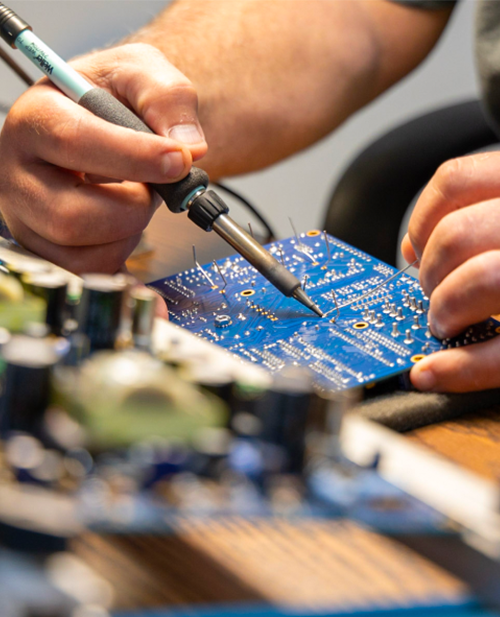

Robotic Automation for Precise Identification

InfoSight offers fully automated robotic identification systems designed to meet the toughest industrial marking challenges. Our robotic automation solutions handle a wide variety of applications, including billets, blooms, slabs, coils, tubes, and pipes. Using robotic arms equipped with durable InfoSight marking or tagging systems, these solutions ensure precise, repeatable identification — even on red-hot or irregularly shaped products.

By integrating robotic automation into your process, you can increase productivity, eliminate human error, and improve workplace safety. InfoSight partners with leading robotic manufacturers and can also integrate with the robot brand of your choice to meet specific plant standards or preferences. Alternate robot selections may involve additional cost or engineering time, but every system is designed for the same proven reliability and long-term performance.

Interested in robotic identification?

Robotic Pin Stamp Marking

Heavy-duty industrial dot peen marking systems from InfoSight create permanent, indented marks for long-term product traceability. They can print alphanumeric characters and 2D barcodes on scaly, rough, curved, irregular, or uneven surfaces, making them perfect for castings, billets, blooms, slabs, plates, and pipes.

Robotic Tagging Systems

We offer automated systems to apply high-quality tags to a variety of products. Tags can be applied to assets such as hot slabs, billets, and coils by welding or nailing, via traditional or robotic automation. Our systems can be designed for a variety of tagging options.

Robotic Laser Marking

Our high-contrast laser marking systems operate by marking a white patch of ink that can be applied to a variety of surfaces. The resulting barcodes are sharp and machine-readable, as well as highly resistant to subsequent manufacturing processes. InfoSight’s laser marking systems operate in a variety of industries, including automotive, steel pipe, and manufacturing.

Robotic Stencil Marking

Automated ink stencil marking is a safer, more cost-effective alternative to manually stenciling products in industrial environments. Each of InfoSight’s spray marking systems, including our fully automated weigh-measure-stencil system, offer superior readability and durability in hot and ambient conditions. Available markings include barcodes and a full range of alphanumeric characters in a wide array of fonts for machine-readable identification.

Design & Build

Robotic Automation Partnerships:

InfoSight partners with leading robotic manufacturers to deliver reliable, high-performance automation solutions. While our primary integrations feature Yaskawa and Fanuc robots, our engineering team can integrate with other robotic brands upon request.